In Gold We Trust

All merchandise listed in our catalog is not for sale through us, except for Miner's Moss and the RP-4 Shaker Table. To purchase any other items, please contact the manufacturers directly. Please note that some items may have been discontinued.

Gold Mining Equipment, Supplies, Prospecting Tools, and Industry Information

|

• HOME

• CATALOG OF EQUIPMENT • FOR SALE & USED, ADS • SUPPLIERS • INSTRUCTIONS, ADVISES • METRIC CONVERSION • Russian - HA PYCCKOM • ENROLLMENT in SALES • OUR CONTACTS |

› |

TV-5 - Horizontal Screening Wash Plant | ||

› |

TV-6 - Horizontal Screening Wash Plant | ||

› |

GEO-T5X - Trailer-Mounted Portable Trommel Plant | ||

› |

S5X - Trommel Plant with Grizzly | ||

› |

GEO-S7 - Skid Mounted Trommel Plant | ||

› |

GEO-S8 - Skid Mounted Trommel Plant | ||

› |

T8 - Portable Trommel Wash Plant | ||

› |

Pre-Grizzly Feeder | ||

› |

Roughing Jigs | ||

› |

Sluice Boxes | ||

› |

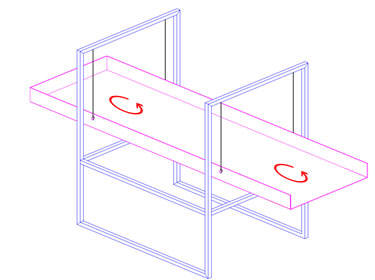

Powered Rotational Material Splitters | ||

› |

Water Separation and Drying Feeder | ||

› |

Lattice Feed Conveyor | ||

› |

Stackable Conveyors | ||

› |

Pumps | ||

› |

Hoses, Clamps, Sheaves, Suction Float, etc. | ||

› |

Generators | ||

› |

Clean Up and Finishing Jigs | ||

› |

Gold Concentration Shaking Table | ||

› |

Additional information about Trommels | ||

› |

GEO Grizzly Belt Feeders | ||

› |

Oscillating Sluice Boxes | ||

› |

Gold Recovery Examples | ||

› |

Why Choose Geolaser - MS for Gold Recovery Equipment? | ||

› |

Custom Designed and Manufactured Trommels for Sale or Rent | ||

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• |

|||

Most photo images are clickable for page-size enlargement |

|||

TROMMELS

|

|||

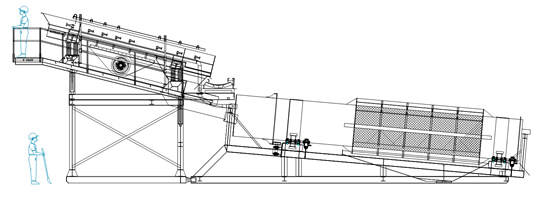

GEO Grizzly Belt Feeders |

|||

|

|||

Why Choose Geolaser - MS for Gold Recovery Equipment? |

|||

We have a long term relationship with a leading gold recovery company, Placer Recoveries Inc., who has over two decades of recovery experience and with over 40 recovery sites, ranging from 50 tons per hour to 1500 tons per hour. Through testing development together we have designed and fabricated many recovery systems over the years from the Yukon throughout the Rocky Mountains. From screens, crushers, sluice boxes, trommels and grizzly feeders to conveyors we work side by side in sharing technology and experience. Capabilities of 12 x 80 Feet |

|||

Oscillating Sluice Boxes |

|||

|

|||

Custom Designed and Manufactured Trommels for Sale or Rent |

|||

|

|||

A Few of our Gold Recovery Examples |

|||

Twin 6x20 screens with twin

6x30 sluice boxes Twin 6x20 screens with twin

6x30 sluice boxes 6x20 screen with a 6x30 sluice box 6x20 screen with a 6x30 sluice box 7x20 screen with a 6x30 sluice box 7x20 screen with a 6x30 sluice box 4x20 vibratory grizzly feeder 4x20 vibratory grizzly feeder |

|||

•• |

|||

Limited Liability Company. Joint Russian American Scientific-Production Company "GEOLASER". |

|||

Address: 630108, Novosibirsk, 1 Trolleynaya Street, Suite 6. |

|||

Telephone: 7 (383) 301-2555. • Cell phone: 7 (913) 911-3592. |

|||

E-mail: office@geolaser.ru (in Russia); larrywilmarth@gci.net (USA, in English).

|

|||

MSI GOLD RECOVERY

•

•

mining producing plants over the years and work side by side with gold recovery companies in developing some of the finest recovery units.

mining producing plants over the years and work side by side with gold recovery companies in developing some of the finest recovery units.